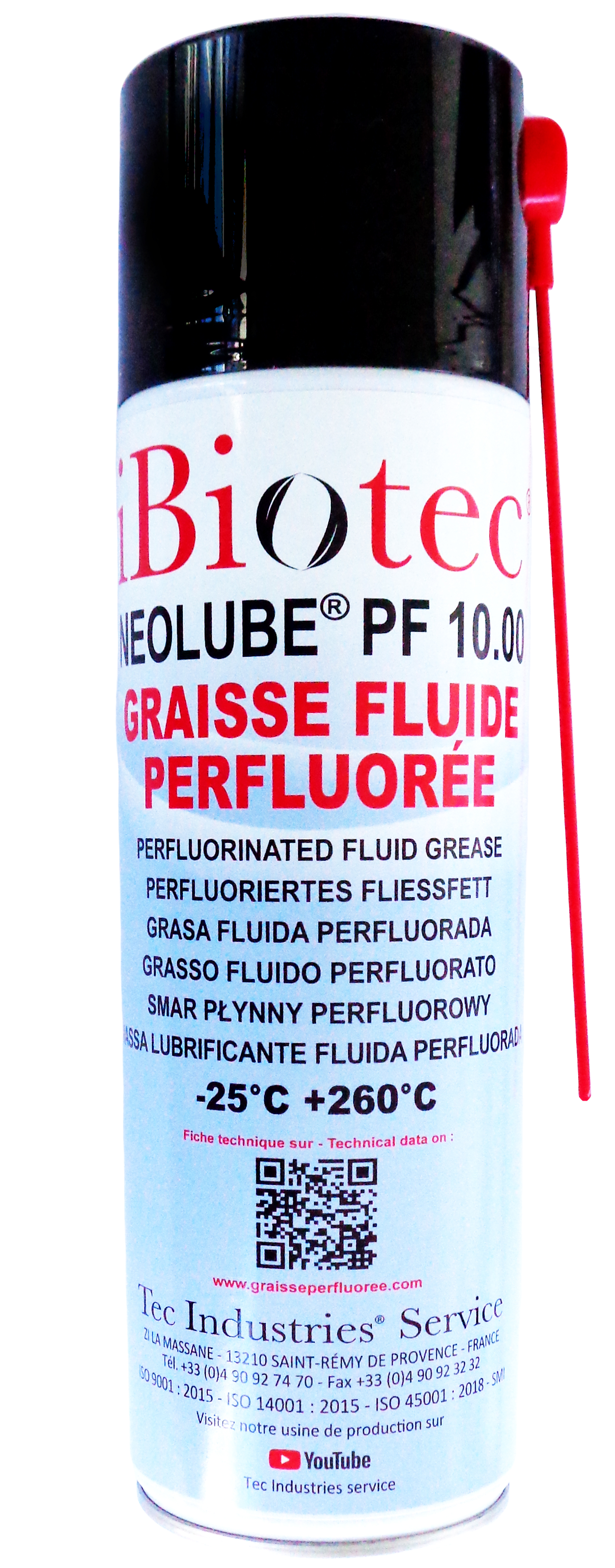

PERFLUORINATED GREASE FOR LUBRICATION

IN EXTREME CONDITIONS

CAN BE USED IN VERY HIGH AND VERY LOW TEMPERATURES AND

UNDER VERY HIGH LOADS

AGGRESSIVE ENVIRONMENTS, COMPATIBLE WITH ALL GASES INCLUDING OXYGEN.

GREASE FOR VACUUM LUBRICATION

VERY LONG-LASTING LUBRICATION, LUBRICATION PROVIDING MAXIMUM SAFETY

NEOLUBE® PF 10.00 IS SUITABLE FOR LUBRICATION IN LARGE NUMBER OF CYCLES

COMPONENTS WITH REDUCED FUNCTIONAL PLAY

DESCRIPTION

Very low volatility in use.

Very high-performance perfluorinated grease offering several advantages.

Suitable for use at very high temperatures, completely resistant to oxidisation.

Insensitive to and unaffected by the majority of solvents, chemical products, acids and bases, water, salt water, steam, including under pressure.

Anti-corrosion, anti-wear. Completely resistant to shearing effects and shock.

Compatible with all metals, plastic materials and elastomers.

Can be used under a stream of liquid or gaseous oxygen, at up to 123 bar, and is inert with regard to all gases.

Grease specifically designed for lifetime lubrication.

FIELDS OF USE

Ejectors used in plastics processing (PF 10.00), drawers and columns.

Production and distribution of gas.

Assembly and lubrication within the electromechanical and home appliances industries.

Lubrication of measurement and precision equipment in the space and aviation sectors.

Compressors, electro-pneumatic and pneumatic equipment.

Chemicals industries. Lubrication in nuclear radiation environments.

Lubrication of machining shops, reproduction shops, bead columns.

Electronics, medical, paramedic and pharmaceutical equipment.

NEOLUBE PF 10 is used to protect against corrosion and oxidation on all surfaces in harsh chemical, highly acidic or alkaline atmospheres.

COMPATIBILITY TESTING OF NEOLUBE® PF 10 AND NEOLUBE® PF 10.00 WITH OXYGEN

tableau1.jpg)

Conclusion: The NEOLUBE® PF 10 AND NEOLUBE® PF 10.00 aerosols can be used under a stream of oxygen at up to 123 bar.

TYPICAL PHYSICO-CHEMICAL PROPERTIES

|

PHYSICAL PROPERTIES OF THE GREASE |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Appearance |

Visual |

Smooth |

nm |

|

Colour |

Visual |

White |

nm |

|

Apparent density at 25°C (pycnometer) |

NF T 30 020 |

1765 |

kg/m³ |

|

NLGI Class |

NLGI National Lubricating Grease Institute |

2 |

Classification |

|

Thickener |

- |

Inorganic |

- |

|

Solid lubricant content |

- |

PTFE telomer |

15% |

|

Penetrability at 25°C Non-worked Worked, 60 strokes Worked, 1,000 strokes Worked, 10,000 strokes Worked, 100,000 strokes |

NF ISO 2137 / ASTM 2176

|

265-295 265-295 265-295 285-315 285-315 |

1/10° mm 1/10° mm 1/10° mm 1/10° mm 1/10° mm |

|

Dropping point Dropping point if greater than 360°C |

NF ISO 2176 / ASTM D 566 ASTM D 2265 |

Without Infusible |

°C

|

|

Impurities > 25 µm > 75 µm > 125 µm |

FMTS 791 3005 |

0 0 0 |

nb/ml |

|

PHYSICO-CHEMICAL PROPERTIES OF THE BASE OIL |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Characteristics of the base oil |

- |

PFPE |

- |

|

Kinematic viscosity at 40°C Kinematic viscosity at 100°C |

NF EN ISO 3104 |

1300 800 |

mm2/s mm2/s |

|

Acid value (AV) |

NF ISO 6618 |

0.0 |

mg KOH/l |

|

PERFORMANCE PROPERTIES |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Oil separation, 7 days at 40°C (bleeding) |

NF T 60 191 |

0.0 |

% of mass |

|

Oil separation, 24 hours at 41 kPa (bleeding under pressure) |

ASTM D 1742 |

0.0 |

% of mass |

|

Sulphated ashes |

NF T 60 144 |

0 |

% of mass |

|

Copper strip corrosion |

ASTM D 4048 |

1a |

Rating |

|

Hoffman oxidation |

ASTM D 942 |

< 1 |

psi |

|

Loss by evaporation, 22 hours at 121°C |

ASTM D 972 |

0 |

% of mass |

|

Noack evaporation loss |

NF T 60 101 CEC L-40 A-93 ASTM D5800 |

0 |

% of mass |

|

Elastomer swelling 70h at 212°F |

ASTM D 4289.83 |

< 0.2 |

Dimensional variation % |

|

Temperature range Continuous Peak |

- - |

-25 +250 -25 +260 |

°C °C |

|

Rotation factor |

n.dm |

100,000 |

mm/min-1 |

|

4-ball test Wear scar diameter Wear load index |

ASTM D 2266 / ISO 20 623 |

0.52 800 |

mm Dn |

|

TIMKEN Test |

ASTM D 2509 |

50 |

lbs |

|

EMCOR rust-prevention test Dynamic Static |

NF T 60 135 ISO DP 6294/ ASTM D 1743 |

0-1 0 |

Rating Rating |

|

Resistance to water washout at 80°C |

ASTM 1264 |

0 |

% of mass |

* not measured or non-measurable

|

ADDITIONAL PROPERTIES |

|||

|

PROPERTIES |

STANDARD OR METHOD |

VALUE |

UNIT |

|

Cold starting torque (-20°C) |

ASTM D 1478-63 |

8 |

N/cm |

|

Operating torque (-20°C) |

|

< 2 |

N/cm |

|

Suppression of operating noise |

FAG MGG 11 |

I |

Classification |

PRESENTATIONS

|

|

Aerosol 650 ml

|

Aerosol 650 ml

|

Looking for another product?

|

Discover our entire range by clicking on the photo |

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.